Cruxtec Consulting Inc has extensive experience utilizing FEA techniques to provide insight into the most challenging engineering problems. With decades of industrial experience delivering high quality results across various industries, Cruxtec works with the clients throughout the project lifecycle to address the needs of the client and provide the added value. The FEA services we provide span over multiple fluid dynamics related areas including:

- Structural analysis including stress distribution, deformation and factor of safety

- Linear and non-linear analysis including contacts and material

- Modal analysis

- Heat transfer analysis including 2-way coupling fluid-structure-interaction

- Random vibration analysis

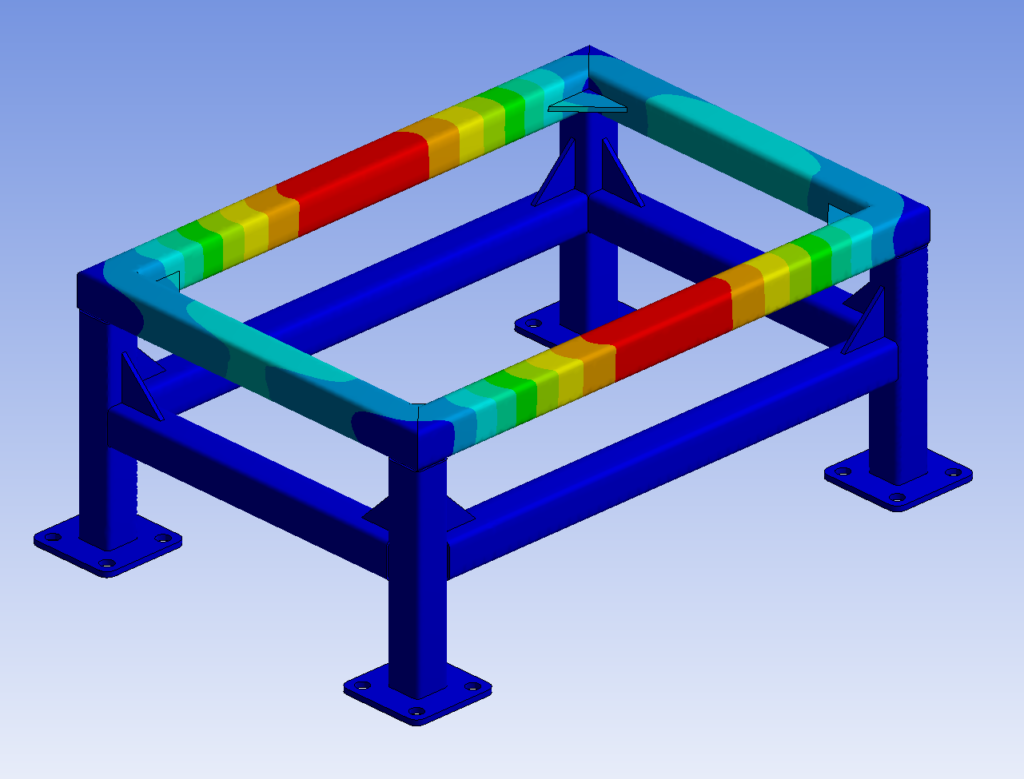

Structural Analysis

The key aspects studied in FEA Structural Analysis include stress distribution, deformation, and factor of safety. Stress analysis provides insights into how different parts of a structure experience mechanical forces, ensuring that materials are not pushed beyond their limits. Deformation analysis predicts the extent to which a structure will change shape under various loads, aiding in the identification of potential weaknesses or design improvements. Factor of safety calculations help determine whether a structure can withstand applied loads without reaching failure, ensuring a margin of safety in the design

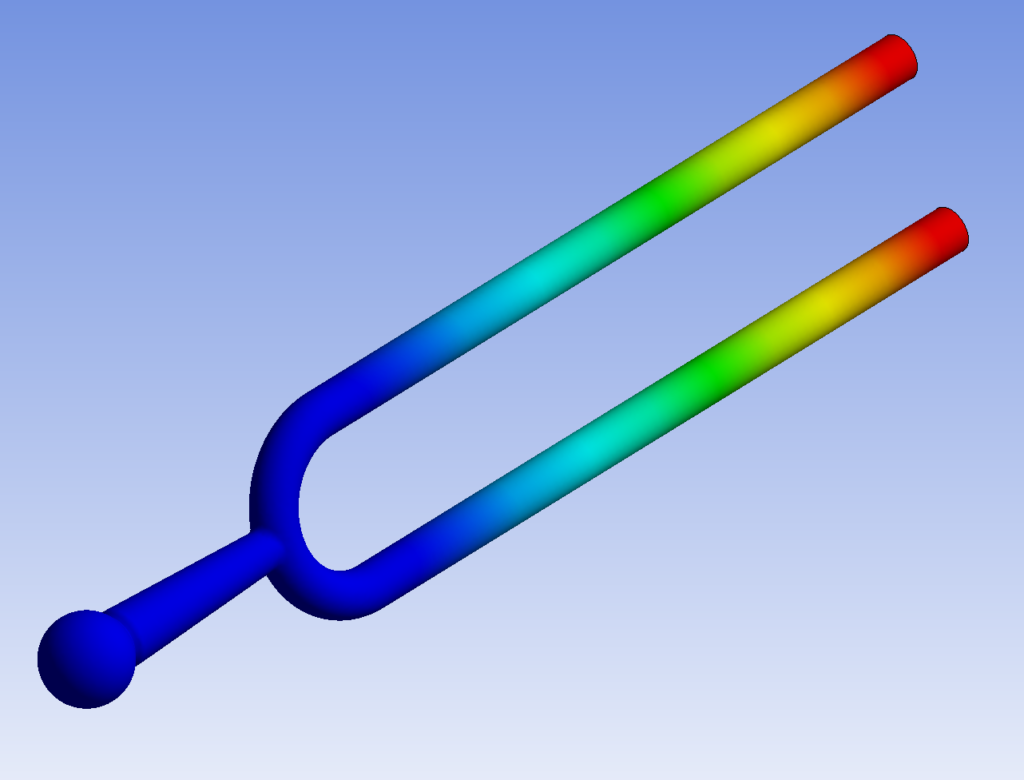

Modal Analysis

The primary focus of Modal Analysis is on understanding the inherent vibrational characteristics of a structure, which are characterized by natural frequencies and mode shapes. Natural frequencies represent the rates at which a structure tends to vibrate in the absence of external forces, while mode shapes describe the spatial distribution of these vibrations.

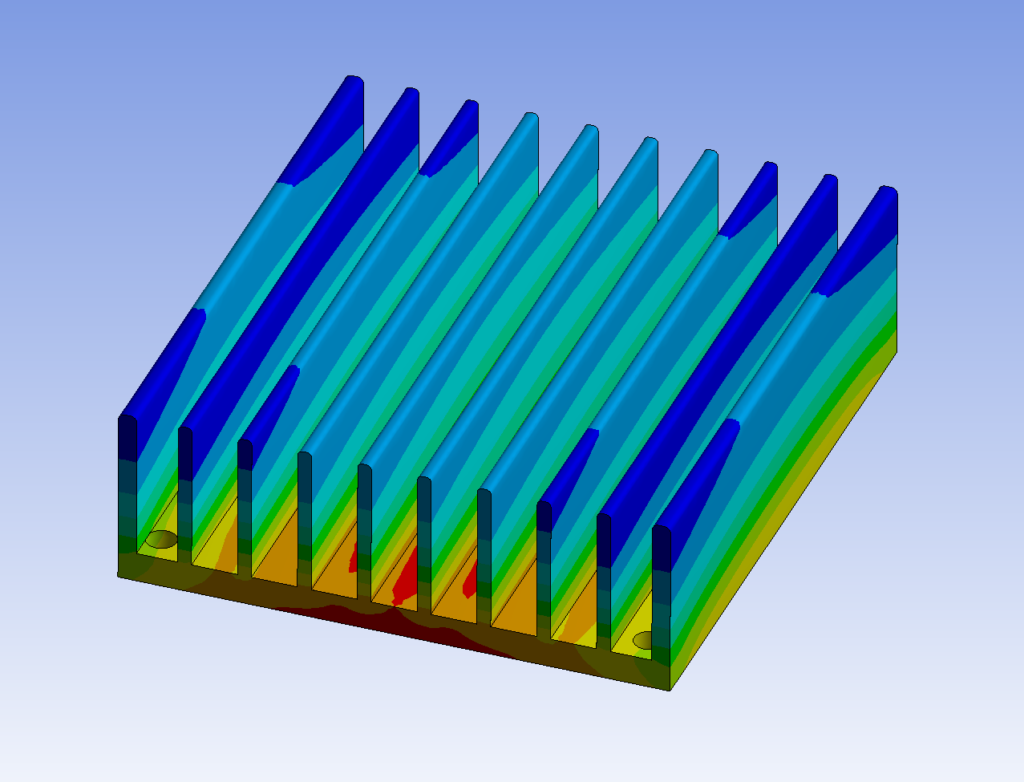

Heat Transfer Analysis

FEA Heat Transfer Analysis finds applications in various industries, including aerospace, automotive, electronics, and manufacturing, where understanding and controlling thermal behavior are crucial for product performance and reliability. It is used to optimize designs, assess thermal management strategies, and ensure components operate within safe temperature limits.

By employing FEA Heat Transfer Analysis, engineers can evaluate different design configurations, predict thermal stresses, and identify areas prone to overheating or thermal inefficiencies.